When most business owners think about data center risks, they focus on the obvious stuff: power outages, network failures, or security breaches. But there’s a whole category of threats hiding in plain sight – tiny physical factors that can slowly destroy your hardware from the inside out: vibration, noise, micro-dust, humidity fluctuations, and electromagnetic interference. These might sound trivial compared to a ransomware attack, but they’re quietly shortening your equipment’s lifespan and setting you up for unexpected failures that could cost thousands.

Here’s what most people don’t realize: your server closet or makeshift data room is probably a hostile environment for sensitive hardware. And the difference between a professional colocation facility and a DIY setup isn’t just about redundant power: it’s about controlling these microscopic menaces that eat away at your equipment 24/7.

The Silent Hardware Killers

Vibration: The Invisible Equipment Destroyer

Your spindle hard drives are spinning at 7,200 RPM or faster while balanced on microscopic bearings. Even tiny vibrations can throw off this delicate dance, causing read/write heads to crash into platters or miss their targets entirely. In server closets, vibration originates from various sources, including HVAC systems, nearby traffic, construction, and even other servers in the same rack.

The worst part? Vibration damage accumulates slowly. Your drives might work fine for months while microscopic wear builds up, then suddenly fail without warning. One day, you’re humming along; the next day, you’re calling data recovery services and explaining to your CEO why the quarterly reports are missing.

Solid-state drives aren’t immune either. While they don’t have moving parts, constant vibration can loosen connections and cause intermittent failures that are a nightmare to troubleshoot. Your server might randomly reboot, applications might crash, or you may experience unusual performance issues that resolve upon restart.

The Acoustic Assault on Your Electronics

Noise isn’t just annoying: it’s a symptom of vibration and a cause of its own problems. High-frequency noise can interfere with sensitive electronics, while the vibrations that create noise can damage components over time.

Server fans are particularly vulnerable. They’re designed to run quietly in controlled environments, not fight against acoustic interference and physical vibration. When fans start failing more frequently than expected, noise and vibration are often the culprits.

The Dust Invasion

Dust is everywhere, and it’s relentless. In an uncontrolled environment, dust accumulates on heat sinks, clogs fans, and forms insulating layers that cause components to overheat. However, what’s truly insidious is that dust conveys static electricity, and when it accumulates on circuit boards, it can cause intermittent shorts and phantom failures.

Even “clean” offices have enough airborne particles to choke server components gradually. And if you’re running equipment in a utility room, basement, or converted closet? You’re basically guaranteeing premature hardware death.

Humidity: The Goldilocks Problem

Excessive humidity can cause corrosion and lead to condensation on cold components. Too little humidity can build up static electricity that can damage sensitive electronics. Most improvised server rooms lack humidity control, relying on luck instead.

Temperature fluctuations make humidity problems worse. When your makeshift server room heats up during the day and cools down at night, water vapor condenses on components, creating micro-corrosion that degrades connections over time.

Real-World Failures You Can’t Afford

These aren’t theoretical problems. Here’s what actually happens when physical factors attack your hardware:

- Hard Drive Carnage: Drives start clicking, seek times increase, and eventually they fail completely. Data recovery can cost $1,000-$5,000 per drive, assuming recovery is even possible.

- Memory Madness: RAM modules can develop intermittent errors due to dust and static. Your servers crash randomly, applications corrupt data, and you spend weeks chasing phantom problems.

- Cooling System Collapse: Fans fail early, heat sinks get clogged with dust, and components overheat. Your servers throttle performance to prevent damage, which makes everything slower.

- Network Nightmares: Dust and corrosion can affect network interfaces, causing packet loss and intermittent connectivity issues that are notoriously difficult to diagnose.

- Power Supply Breakdown: Dust buildup causes power supplies to overheat and fail, taking other components with them when they die.

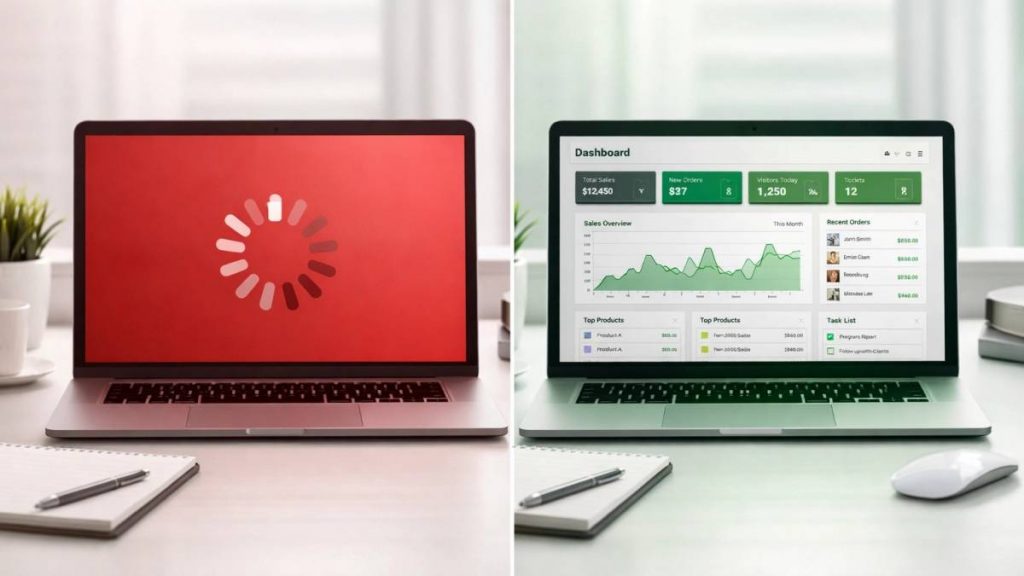

Why DIY Server Rooms Fail at Environmental Control

Most businesses try to save money by repurposing office space for servers. They’ll stick equipment in a converted closet, spare room, or corner of the warehouse and call it a “data center.” But these spaces are environmental disasters waiting to happen.

Office HVAC systems aren’t designed for server heat loads. They can’t maintain precise temperature and humidity control, and they often create turbulent airflow that spreads dust and creates hot spots. The vibration from commercial HVAC equipment alone is sufficient to shorten drive life significantly.

Converted spaces often lack proper filtration, allowing outdoor pollutants, construction dust, and office debris to circulate through your equipment. There’s no vibration isolation, so every footstep, door slam, and passing truck transmits directly to your servers.

And let’s be honest about maintenance: when was the last time you replaced the air filters in your server closet? Do you even have air filters? Most improvised setups get ignored until something breaks, which means environmental problems compound over time.

How Data Center Colocation Solves Invisible Problems

Professional colocation facilities like Datacate shine in thwarting these invisible equipment destroyers. We don’t just provide power and internet: we engineer environments that eliminate the physical threats your hardware faces every day.

Precision Environmental Control

Our data centers maintain input air temperature in the range of 60-65º F and 40% – 60% RH. This isn’t just comfort: it’s equipment protection. Precise control prevents condensation, reduces static buildup, and maintains components within their optimal temperature range for maximum lifespan.

Advanced Filtration Systems

Professional filtration removes dust particles down to one micron, ensuring dust never reaches your equipment. Our multi-stage filtration systems create positive-pressure environments that actively exclude contaminants. Your servers operate in clean air 24/7, which dramatically extends the life of components.

Vibration Isolation

Data center floors are engineered to isolate vibration. Raised floor systems with proper dampening prevent vibrations from building operations, nearby traffic, or other equipment from reaching your hardware. Your drives operate in the stable environment they were designed for.

Acoustic Engineering

Sound levels are controlled through the use of acoustic panels, proper equipment placement, and effective airflow design. Lower noise levels result in reduced vibration and improved operating conditions for sensitive components. Your equipment runs quieter and lasts longer.

Proactive Monitoring

Environmental sensors continuously monitor temperature, humidity, particle counts, and vibration levels throughout the facility. If conditions start to drift outside optimal ranges, systems automatically adjust before problems develop. You get the benefits without having to become an HVAC expert.

The Bottom Line: Prevention vs. Recovery

Here’s the math that makes colocation obvious: replacing a failed drive costs between $300 and $2,000, depending on the size and speed. Data recovery costs an additional $1,000 to $5,000. The downtime required to rebuild systems incurs additional costs in lost productivity and eroded customer confidence.

A professional colocation environment helps prevent most of these failures from occurring in the first place. Your equipment lasts longer, performs better, and fails less frequently. The monthly cost of proper environmental control is a fraction of what you’ll spend on premature hardware replacement and emergency repairs.

Plus, you get peace of mind. Instead of worrying about whether your server closet is slowly killing your hardware, you can focus on running your business while professionals handle the environmental engineering.

Your Hardware Deserves Better

The physical threats facing your equipment may not be dramatic, but they’re relentless. Every day your servers operate in an uncontrolled environment, microscopic damage accumulates. Dust builds up, vibrations cause wear, humidity corrodes connections, and temperature fluctuations stress components.

Professional colocation isn’t just about redundant power and fast internet: it’s about creating the optimal environment for your hardware to thrive. At Datacate, we’ve engineered our facilities to eliminate the invisible threats that cut equipment life short and cause unexpected failures.

Ready to give your hardware the environment it deserves? Contact us to discover how our colocation services safeguard your investment and mitigate the hidden risks that could be costing you thousands in premature hardware replacement.